This blog is written by Erik Schettig (teacher in the RET program) and Dylan Overton (student in the young scholars program) and is part of their program activities.

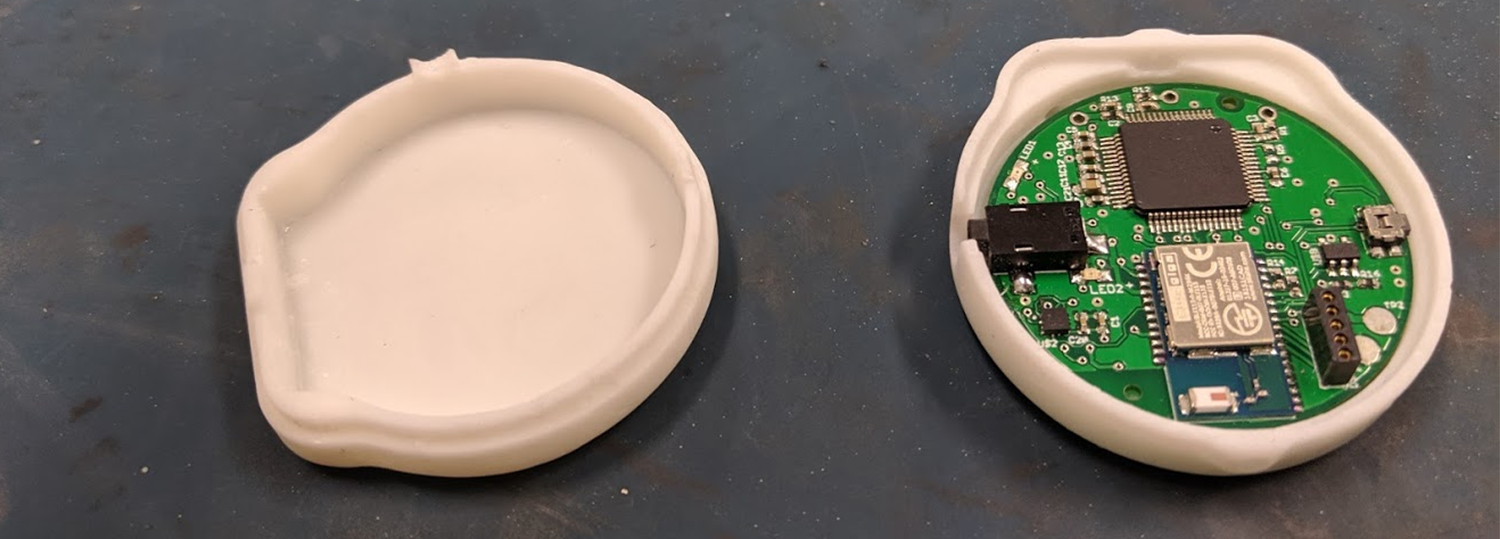

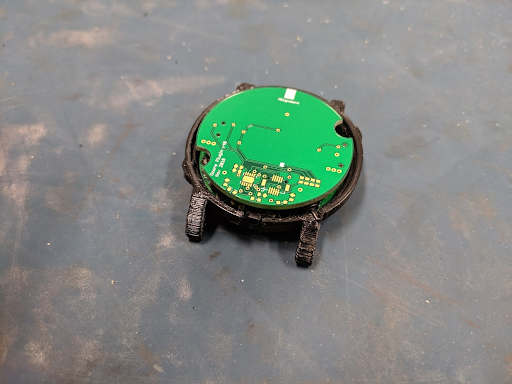

Last week, Erik and Dylan started testing their boards but identified areas of improvement. Therefore, this week, they worked on sanding the shells for the chest patches and printed the shells. Generally, the shells must be sanded to fit the boards inside. Unfortunately, the shells were a little too small, and while putting the boards in some of the bottoms, the bottom of the shell would crack. Consequently, they had to print out new bottoms for those tops with cracked bottoms. Lastly, by using Autodesk Fusion 360, they edit the designs of the shells to have the boards fit better. Erik and Dylan then got to observe the app connected to the wristband and chest patch accelerometer. Whenever the user moves around, the app livestreams the data.

This week, the student-teacher pair also toured Wilson College of Textiles and learned about cloth and string manufacturing. They saw the weaving looms and cotton spinning machines, and the dye printing machines. last but certainly not least, Erik and Dylan also worked on their wearable device challenge projects for next year.