This blog is written by Erik Schettig (teacher in the RET program) and Dylan Overton (student in the young scholars program) and is part of their program activities.

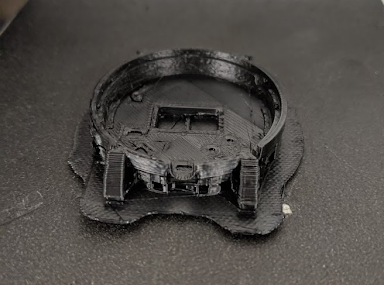

During their last week of the ASSIST RET and young scholars program, Erik and Dylan continued working on their 3D-printed cases for their wearable device. This week though, they used ABS filament in the 3D printer instead of PLA filament. However, the printer used didn’t get hot enough to allow the ABS filament to cool slowly which caused the piece to warp. To fix this problem they tried changing the temperature of the extruder from 230°C to 245°C. Doing so only worked with small pieces and unfortunately barely helped on any bigger piece. In the end, the student-teacher team switched back to PLA filament. The PLA material performed much better and allowed for more precise prints which were also easier to sand.

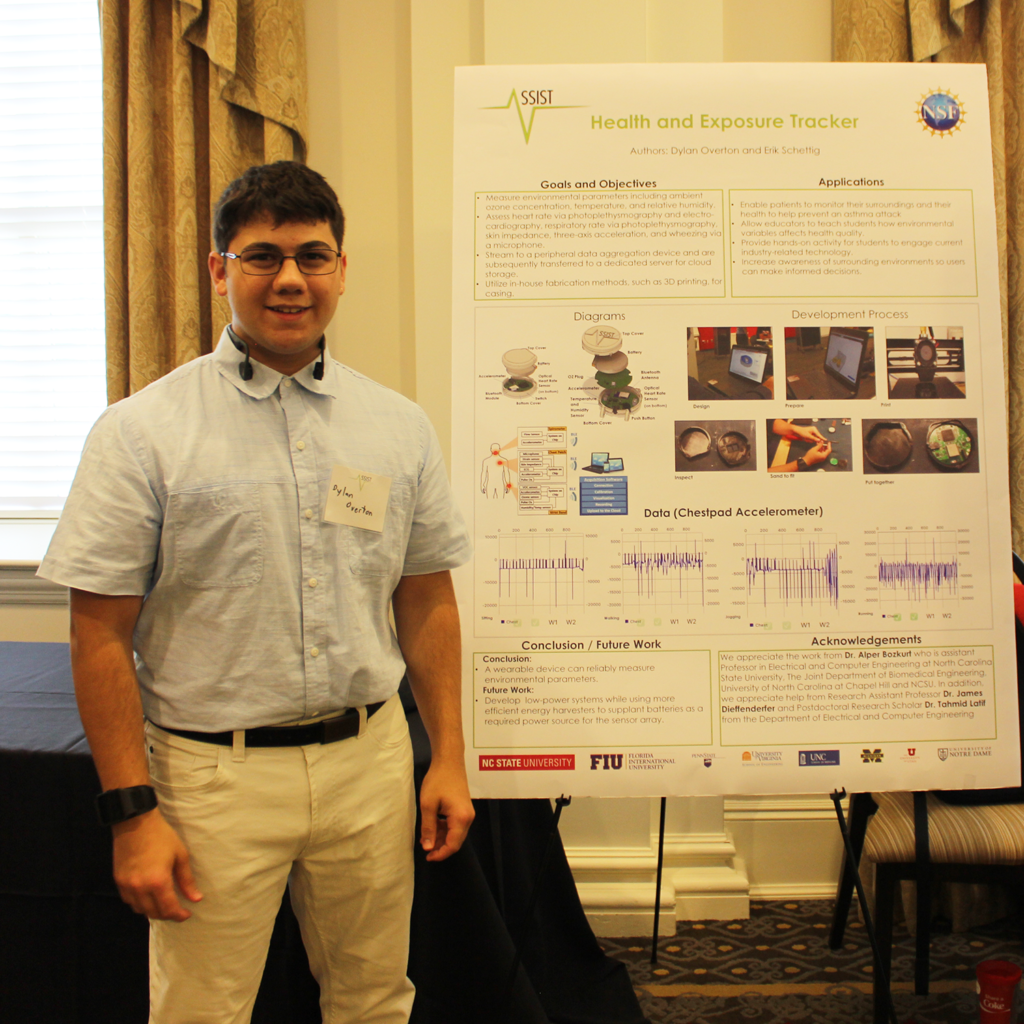

Since Dylan and Erik had to present their research at the annual Summer REU Research Symposium held on July 26, they put together their presentation poster. At first they included basic information and diagrams from previous reports. Since some of the diagrams were outdate, the team used Fusion 360 and Eagle CAD files to design new diagrams of the devices. The poster was presented to supervisors who provided feedback on changes. Some of the changes included adding information and including data charts. These changes were made and the poster was finalized.